II. The functions of Hydraulic Lifting Bollards

1. Hydraulic Lifting Bollards can block and restrict the entry and exit of passing vehicles, and prevent vehicle damage to pedestrians, major facilities, and buildings.

2. You can use it as a guardrail to set a boundary, delineate a specific area, isolate pedestrian traffic and vehicle channels, etc., which prevent effectively terrorists or other thugs from driving maliciously to crash the checkpoint and protect the traffic order and the safety of the place.

3. The beautiful appearance of the bollards also beauty the environment.

4. Sometimes it even serves as a chair for us to sit down and enjoy lunch.

III. Application of Hydraulic Lifting Bollards

Hydraulic Lifting Bollards are widely used in urban transportation, the military, and the gates of important national organs. E.g.,

Traffic Light Intersections, Airports, Subways, Highway Toll Stations, Gas Stations, Garages, Parking Lots, Prisons, Troops, Government Units, Company Gates, Factory Gates, Parks, Scenic Spots, Sports Venues, Stadium, Squares, Shopping Malls, Supermarkets, Pedestrian Streets, Farmers’ Markets, Exhibition Halls, Schools, Hospitals, Banks, Embassies, Large Clubs, Hotels KTV, Villa Areas, Logistics Centers And Many Other Places.

Different categories of bollard applications

1. Full-Automatic Bollard

We can use it in places with more vehicles in and out, which need frequent raising and lowering. What’s more, it’ll be better if equipped with security guards around.

2. Semi-Automatic Bollard

Customers can put it in places with fewer vehicles passing and no need to raise and lower frequently. Or a place without security guards nearby. E.g., pedestrian streets, squares, etc. Besides, you can choose it to use together with a full-automatic bollard for some entrances and exits with larger widths.

Advantages: Lower cost + Higher anti-theft security without control

3. Removable Bollard

You can install it in places with fewer vehicles, which basically no need to lift and fall. What’s more, there are security guards on duty.

The security guard needs to dismount the upper cylinder and remove it manually when the vehicles pass, so the cylinder is generally thinner and lighter. It mainly plays a schematic effect, and the anti-impact ability is weak.

4. Fixed Bollard

It is mainly used together with full-automatic or semi-automatic bollards.

IV. Category of Bollard

- According to the different working methods, we can divide it into the following 4 categories.

1- Full-Automatic Bollard

Customers can set the legal authorization information to automatically complete the bollard’s rise and fall. It includes below 2 different types.

(1) Pneumatic Full-Automatic Bollard

The driving medium is air. We drive the rise and fall of the cylinder through an external pneumatic power unit. We used it in the early times. Now, it’s replaced by the latest Hydraulic Bollard

(2) Electromechanical Hydraulic Integrated Full-Automatic Bollard

The driving medium is hydraulic oil. We drive the cylinder rise and fall through the motor built into the cylinder.

It has been the mainstream product in the current market, with the below advantages.

Beautiful appearance, easy operation, fast action, low noise, safe and reliable, waterproof, anti-rust, anti-theft, anti-slip, anti-freeze, anti-collision, overload protection, safety warning, low noise, stable operation, long service life, etc.

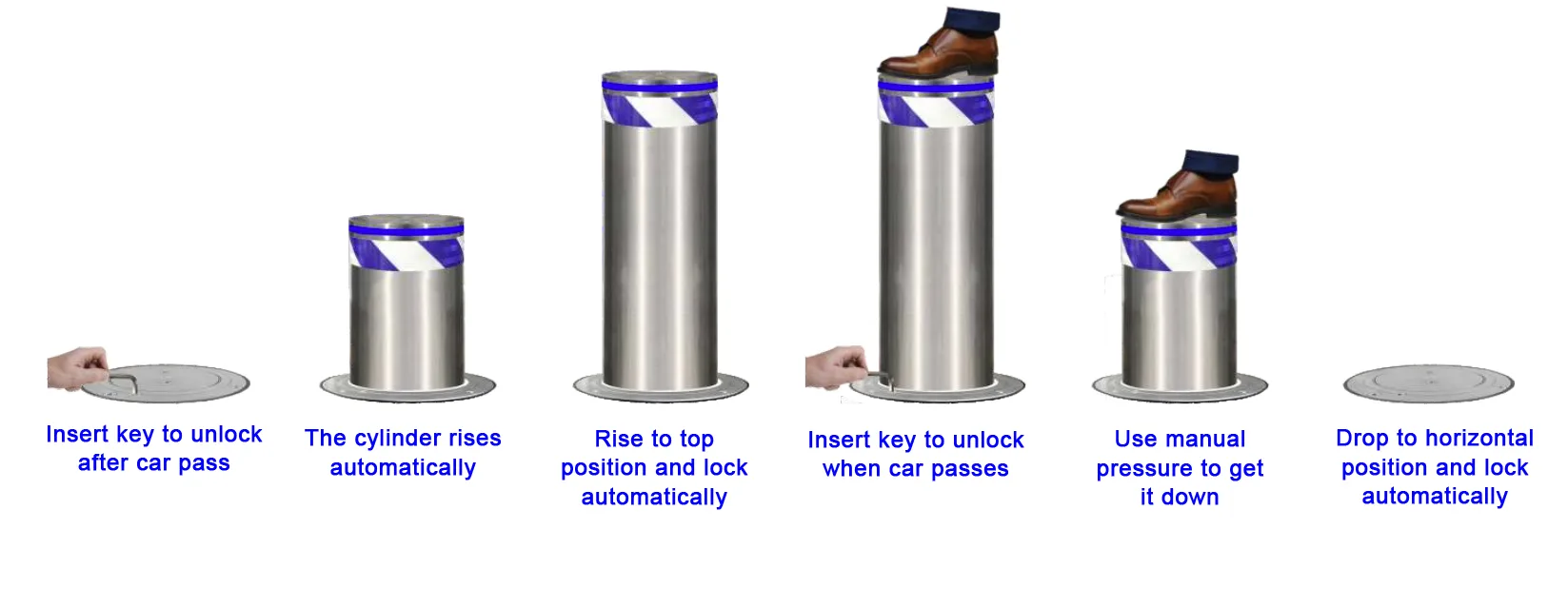

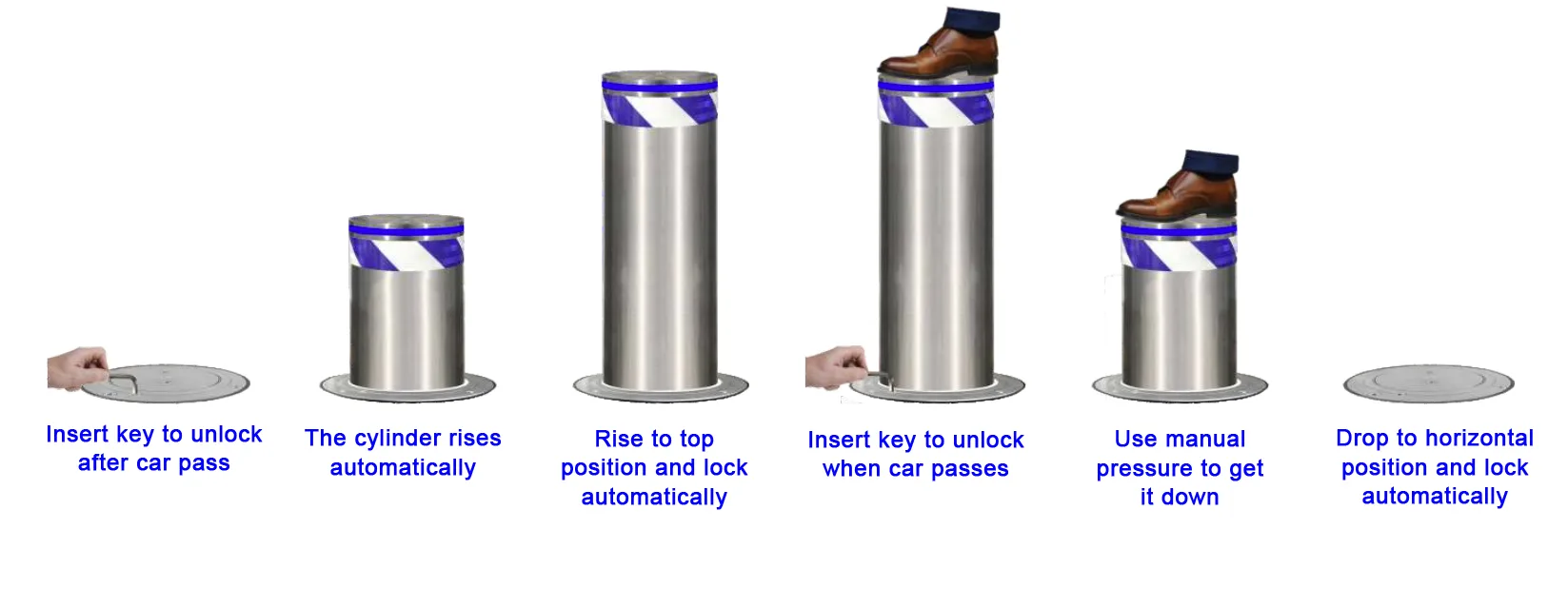

2 – Semi-Automatic Bollard

Users can lock and open it with a manual key. It includes the below 2 types.

When the car passes, pls first use the key to open the bollard in the raised state. Then use our foot or manual pressing to let it down. Once in place, it’ll lock automatically. After the car passes, we use the key again to open it, and it will automatically rise by the power unit inside the cylinder.

(2) Manual lifting rise semi-automatic bollard

The rise needs our manual lifting, and the fall depends on the weight of the bollard itself.

3 – Movable bollard

The upper column on the ground and the bottom base under the ground adopt a separate design and no need for deep burial. User can remove manually the upper column when the vehicle pass.

4 – Fixed Bollard

The upper column part on the ground is the same as the full-automatic and semi-automatic bollards in appearance and materials. The difference is that we just fix it on the ground, which makes it neither move up and down nor move left and right.

- We can classify the bollard as the below 2 types if according to the safety protection level,

1 – Civil Bollard

2 – High Safety Bollard

- As the driving way, we can classify the bollard as

1-Manual Bollard

2-Air Pressure Bollard

3-Electric Bollard

4-Hydraulic Electric Bollard

VI. Features of Hydraulic Lifting Bollards

1 – Electromechanical hydraulic integrated

Hydraulic Lifting Bollards adopts the international leading electromechanical hydraulic integrated movement drive technology. The whole system is reliable with high safety and high stability.

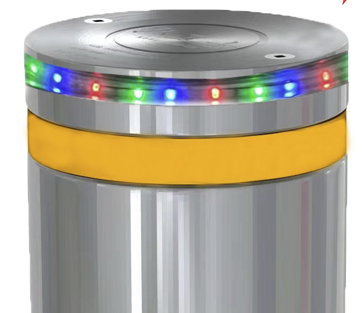

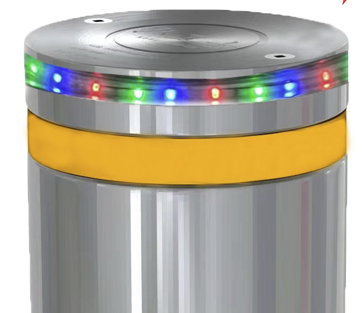

2 – Warning direction light

(1) The top uses an ultra-high-bright LED warning direction light, which has an effective warning at night.

(2) You can set it to turn the light on when rises and turn it off when falls.

(3) Users can also set the automatic lighting time and automatic closing light time by the control system box, such as You can turn off the warning light during the day, and turn it on only at night.

(4) The remote controller of the warning light: We equip it with a touch remote controller. The available remote controlling distance is 30m, and you can adjust the light color by it.

(5) Warning light protection plate: In order to better protect the warning light belt, we specially produced a reinforced acrylic protection plate to reduce wear.

3 – Reflective film

We adopt 50mm high-intensity reflective film.

4 – Control way

You can control the rise, fall, and pause of the bollard in the below ways.

(1) Wireless remote controller

******** There are 3 buttons on the wireless remote controller, namely, rise, fall, and stop. You can use them to control the rise, fall, and pause of the bollard.

******** Available remote control distance range: 50m.

******** You can divide first into some groups for many sets of bollards. Then control them separately by group. Besides, you can also choose the collective control at the same time. For example, there are 8 pcs bollards in total. You can first divide them into 4pcs for each group. Namely, there are 2 groups. You can operate only one group at a time. What’s more, you can also operate them all 8pcs at the same time

(2) Distribution box control system button

There are rising, falling, and stopping buttons in the distribution box. You can use them to control the rising, falling, and suspending of the bollards.

(3) External wired switch

(4) Emergency switch

Emergency measures in emergency situations: When the power is off, longly press the combination button – the fall button and the stop button in the control box at the same time, and the cylinder will fall. If the cylinder doesn’t move down, can manually press it down until the cylinder drops to the level of the ground.

(5) Mobile APP control software

(6) PC-side Internet of Things remote control

5 – Combined Control with strong compatibility

*** Hydraulic Lifting Bollards has a reserved card reader opening interface, ground sense detection signal interface, infrared signal interface, and fire-fighting linkage signal interface. You can control them jointly by connecting them with car license plate recognition, vehicle barrier gate, face recognition terminal, access control system, monitor, infrared sensors, Bluetooth, radar, ground sense, sound and light alarm, traffic light system, tide lane, fire alarm system, etc., supporting compatibility with any opening signal.

*** The fire-fighting linkage signal is prior to the remote control and wired button signal. It’s the highest level of signal. When triggered, the bollard will descend.

*** The control program adopts single-chip control, which is convenient for system combined control.

6 – Emergency control

When the power is off, in order not to affect the normal passage of the vehicle, you can use manual operation to control the Hydraulic Lifting Bollards rise and fall.

We equip an emergency battery EPS and combined buttons. Long press the combined buttons – the drop button and the stop button at the same time, and the bollards will lower automatically. If the cylinder doesn’t move down, you can manually press it down until the cylinder drops to the level of the ground.

7 – Speed

The rise time is 4S, and the fall time is 2.5S.

8 – Structure:

(1) The upper cylinder on the ground:

*** Material: 304 stainless steel tube

*** Size: Thickness 6mm* Diameter: 219mm* Height: 600mm (customizable)

(2) The lower cylinder under the ground:

*** Material: iron + paint cylinder, better rust resistance.

*** Size: Diameter 325mm* Height 785mm (customizable)

(3) The middle Flange plate:

*** Material: stainless steel + iron with paint plate, better rust resistance.

*** Size: Thickness: 26mm=6mm stainless steel +20mm iron plate, diameter: 430mm

9 – Motor

(1) Waterproof grade: IP68 and above, can work directly in water.

(2) There is no leakage in the state of immersion, and we can still use it normally

(3) After immersing it in water for a 120h test, connect it to power, and it can rise and fall normally.

(4) Motor power: 350w.

(5) It contains thermal protection devices.

(6) Corrosion resistance test: 10 grade (no rust points)

10- Buried Cylinder underground

*** We add anti-rust paint on the surface. It has no bubbles, shedding, and lamination phenomenon after 24h neutral salt spray test.

*** This model adopts sealing structure design, no need a drainage system in the bottom. Shallow buried depth help reduce construction costs.

11- Real vehicle anti-collision certification

***KKH bollard has passed the Ministry of National Public Security real vehicle anti-collision testing standard “GA/T 1341-2016” certification, and has reached the highest A3 level of the standard!

*** Test sample: hydraulic cylindrical structure bollard. Its blocking cylinder body on the ground is made of 20mm thick stainless steel.

*** Test result: Blocking ability grade: A3 (i.e., test vehicle intrusion distance: 12.7m, vehicle weight =6800kg, collision speed =80km/h, collision energy: 1679000J)

12- external wiring design

As we all know, there are many wires in the cylinder under the ground, and the main one is the one that supplies power to the movement. Many bollard manufacturers place it inside the cylinder, which makes it easy to damage the line due to the friction when the movement pushes the cylinder up and down. Lastly, result in the bollard can’t continue working. In order to avoid the harm of this problem, we use an external wiring design.

13- Location of the wiring hole

Based on our rich experience, we designed the wiring hole to the top position of the cylinder under the ground. It avoids electric leakage caused by the wiring hole position being too low and the rain entering the cylinder. Meantime, it also prevents the wires from breaking caused by the vertical pressure resulting from the higher wiring hole position.

14 – Voltage

Power Supply: AC 220V, Control Voltage: 12V

15 – Leakage Protection

We installed a leakage protection device on it.

16 – Operating temperature: -30℃~55℃

17 – Strict testing

Each step of the production for KKH Hydraulic Bollard has strict technical control, and only the finished product passes some required tests that enter the qualified finished product warehouse, such as the rise and fall test, temperature difference detection, power failure test, etc.

18 – Simple installation and wiring

Connecting it to the controller with 3*1.5 core and 4*1.0 core wires is OK.

19 – Guarantee:

1 year

20 – After sales:

lifelong maintenance support + free guidance

21 – Support customization, OEM

You can customize the style, size (thickness, diameter, height), speed, logo, etc. The following sizes are optional:

(1) The upper cylinder on the ground

******** Length: 400mm,600mm, 800mm

******** Diameter: 168mm, 219mm, 273mm, 325mm

******** Thickness: 6mm, 8mm, 10mm, 12mm,… 18mm, 20mm

(2) The lower buried cylinder under the ground

******** Length: 550mm (It’s suitable for telescopic/retractable two-section bollard), 785mm, 1100mm

******** Diameter: 284mm, 325mm

VII. How to choose a suitable bollard and reliable manufacturer?

1- Categories

First of all, pls consider which type of bollard you need to install for the occasion.

*** Although all bollards have the function of blocking vehicles, the blocking on vehicles effect between the civilian bollards and professional anti-terrorism bollards is a world of difference. When it refers to safety protection applications, it is necessary to consider the vehicle’s size and speed of collision.

*** For some of the most security-sensitive places, such as Important Government Organs, Schools, Banks, Prisons, The Military, Nuclear Power Plants, Natural Gas Stations, Energy Storage And Transportation Stations, Power Grid Substations, Embassies And Consulates, Border Crossings, etc., need to use a higher level of security protection and anti-terrorism bollard. It has a high anti-impact rating and can generally withstand the impact of at least 6.8 tons of trucks at 65km/h. The diameter of the blocking cylinder is above 273mm, the thickness is above 15mm, and the blocking height is above 800mm.

*** Concerning the general civil-level bollard, the collision resistance level is medium. It can resist the maximum impact of 2.3 tons of vehicles at 100km/h speed. The cylinder diameter is generally 219-233mm, the thickness is 6-10mm, and the blocking height is 600-800mm.

Although the performance is slightly worse than the bollard with a higher anti-terror level, its protective performance can fully meet the needs of civil security. At the same time, the price is moderate, the appearance is beautiful, and the use is more frequent in daily life. It is mostly used in urban areas where people are easy to gather, vehicle flow is large, and vehicle access control places with medium safety requirements, such as Schools, Hospitals, Parks, Pedestrian Streets, Luxury Stores, High-End Villas, High-End Office Buildings, Industrial Parks, Research and Development Centers, Public Performances or Exhibition Venues, Power Stations, Highways and other places.

2 – Quantity needed

Select the appropriate number of bollards according to the application scene width, traffic flow density, terrain, etc. factors.

Generally, the foundation distance between adjacent cylinders should not exceed 1.5 meters. 0.8-1.2m is available.

3 – The frequency of rise and fall

If the vehicle is in and out frequently, and the use frequency of the bollard is high, it’ll be better to choose the bollard with better performance, such as the hydraulic full-automatic bollard.

4 – Group management

Whether the lanes need to be separated or managed in groups by lanes determines the configuration and selection of the entire control system.

5 – Rainfall and drainage

Because the bollard is buried deep below the ground, it is inevitable that it will be soaked in water when rains. If the application place has large rainfall, often has heavy rain, low terrain or shallow subsoil drain, or no drainage system, pls choose the bollard with at least IP67 grade above, so as to better ensure safety.

6 – Security

Safety first! Bollards must meet various safety standards to ensure that they do not cause accidents during use. Such as

(1) Whether it meets the national industry standards.

In 2016, China launched the standard for evaluating the Bollard industry, and named it “anti-riot lifting type blocking car roadblock”, and the industry-standard execution number “GA/T1343-2016”

(2) Do the bollards meet the requirements of anticollision grade?

***Bollard is anti-collision security equipment. Its main function is to prevent vehicle break-ins, personnel hurt, and property loss caused by driver misoperation, so its own anti-collision ability is the most important parameter we need to investigate. In fact, only the bollard that is able to effectively block or intercept vehicles is a really qualified product.

***KKH bollard has passed the Ministry of National Public Security real vehicle anti-collision testing standard “GA/T 1341-2016” certification, and has reached the highest A3 level of the standard! It ensures the high safety of the product, giving users more peace of mind.

(3) Explosion-proof device

Equipped with explosion-proof devices and safety limit switches to ensure that they do not fail due to overload or other reasons.

7 – After-sales service

The standard to measure a bollard enterprise is not only the appropriate quotation, stable performance, and high-quality products, but also premium service support! The bollard industry competition is very fierce, many manufacturers’ product functions and solutions are similar, but the level of service is very different. Many dealers are in a hurry to compare manufacturers, and technical parameters when bidding, often ignoring the service level. After the project was completed, there was no corresponding service when customers needed technical support.

KKH has a professional service team, from demand research, tailored solutions, delivery, installation and commissioning, and warranty, to lifelong after-sales maintenance, providing you with a full set of reliable one-stop solutions. If a problem occurs after delivery, our professional technical team will give priority to dealing with it, help you solve the problem in the short term, and let the product return to normal work ASAP.

8 – Manufacturer’s reputation

Good manufacturers usually offer higher quality and more reliable products. We KKH exist mainly depending on the higher quality and reputation. Pls give us a chance, believe will bring you more, and we hope to become your long-term partner in business and lifetime loyal good friends in life.